Vacuum Brazed Liquid Cold Plate

Vacuum brazing is a material joining technique that offers significant advantages: extremely clean, superior, flux-free braze joints of high integrity and strength.

Vacuum brazing is a material joining technique that offers significant advantages: extremely clean, superior, flux-free braze joints of high integrity and strength.

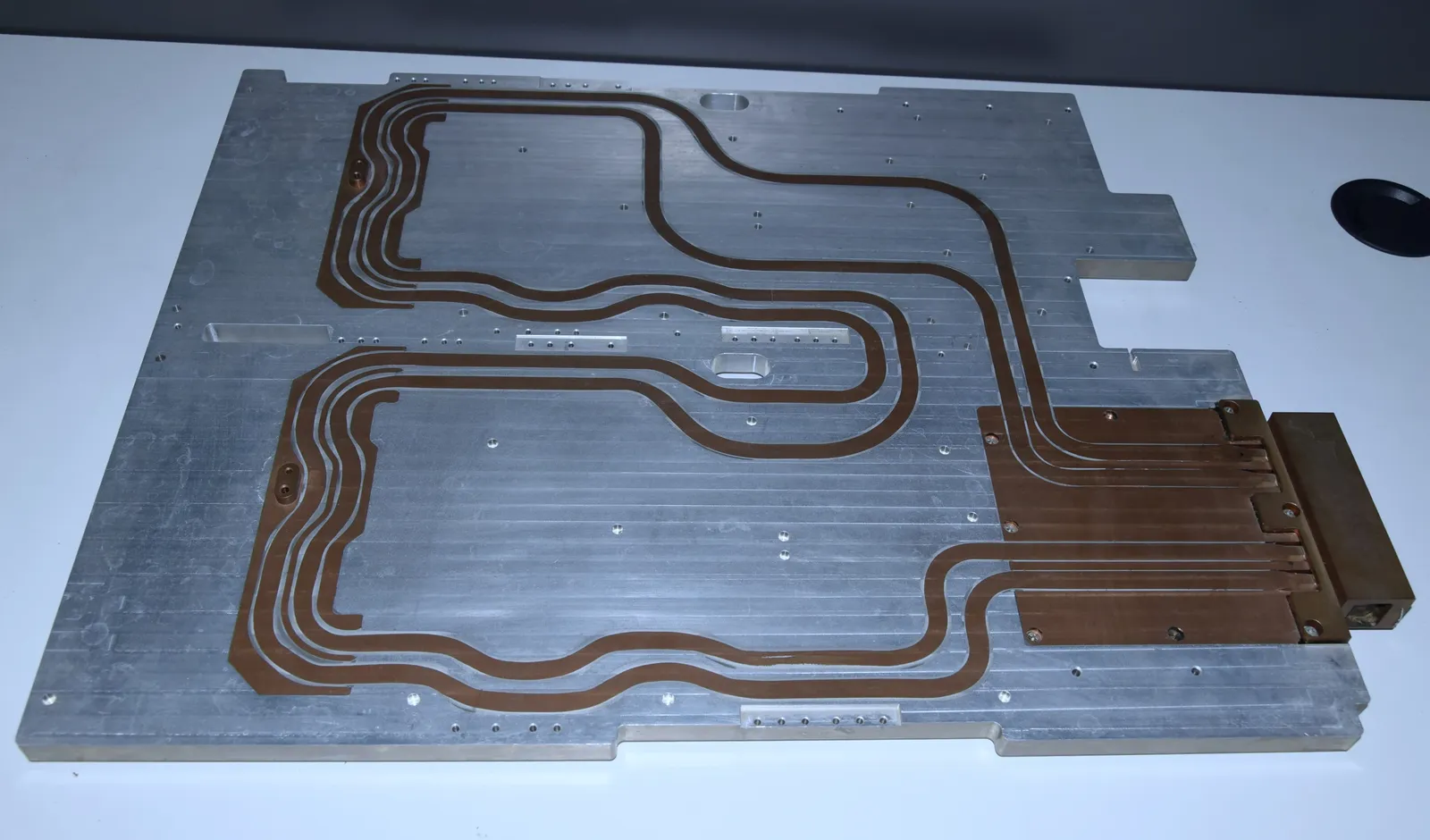

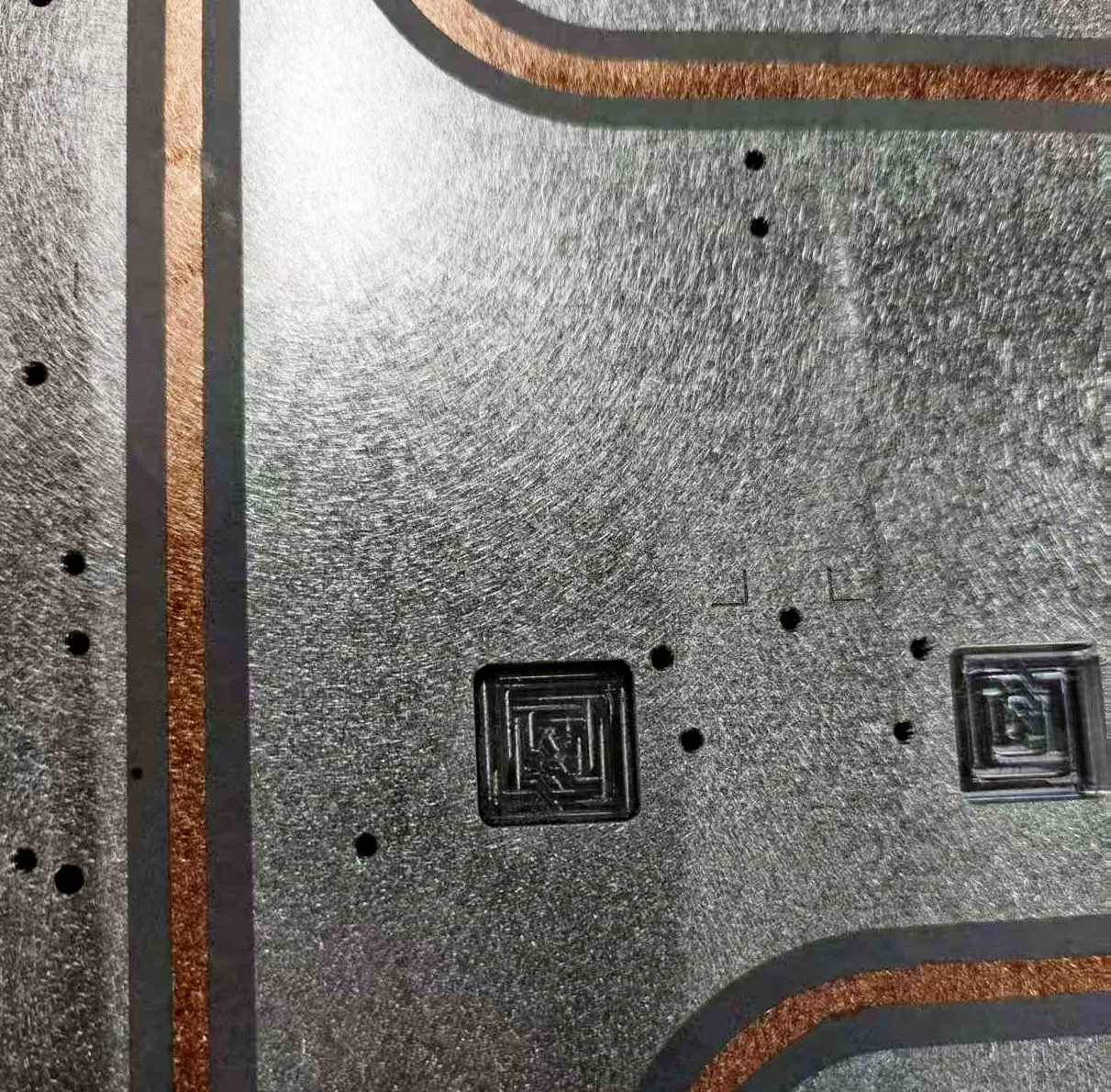

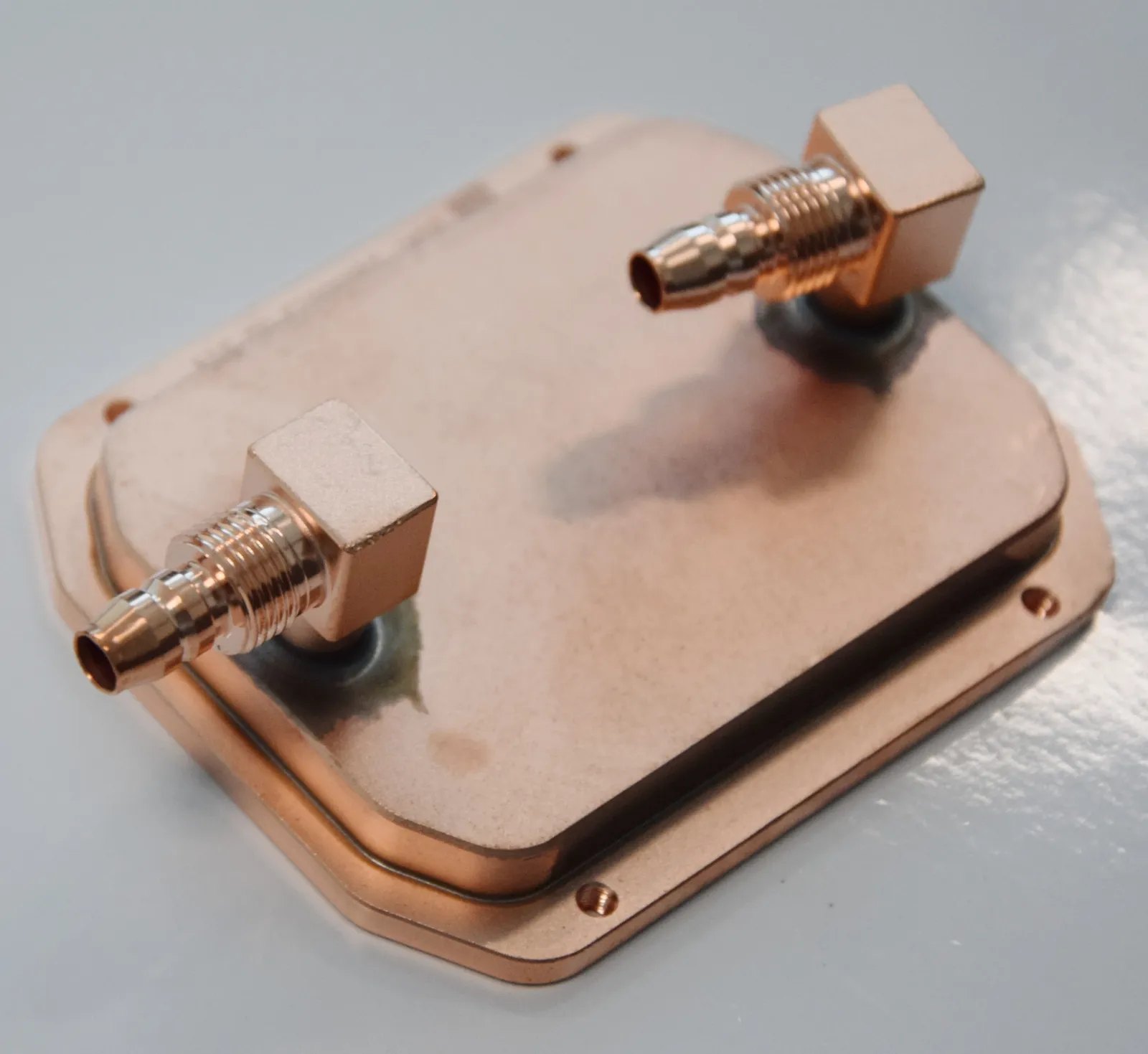

Vacuum brazing is a manufacturing process that joins together components using a filler metal called a brazing alloy, often conduct in a furnace. Vacuum Brazed Liquid Cold Plates use this principle to realize the connection of aluminum or copper base plate, composite brazing material plate & cover plate.

Vacuum brazing is a material joining technique that offers significant advantages: extremely clean, superior, flux-free braze joints of high integrity and strength.

Vacuum brazing prevents oxidation and contamination of the joint surfaces, resulting in clean, oxide-free joints that do not require any other finishing or cleaning.

HY thermal Tech is ISO 9001:2015-certified, IATF-registered, and RoHS-compliant manufacturer since 2006.

We have expertise and experience in Liquid cooling systems, CNC machining, and brazed joint assemblies for high-precision components more than ten years.

Whether you have a question regarding our factory or certifications or are interested in discussing a new project requirement, we're always ready to talk.

Let's Going on

| Parameter | Details |

|---|---|

| Making process | CNC machining + epoxy bonding |

| Types of Welding Processes | TLP/FSW/Vacuum Brazing/Laser Welding |

| Size | Custom |

| Material | Aluminum (optiona), Copper (standard) |

| Operating Temperature | -40°C to 100°C (typical range; exact values depend on design) |

| Thermal Resistance | 0.05°C/W (typical; exact values depend on design) |

| Flow Rate | 1-5 L/min (typical; exact values depend on design) |

| Pressure Drop | <0.1 bar (typical; exact values depend on design) |

| Certifications | ISO9001:2015 certified |

Note: Specific thermal performance metrics may vary based on custom design. Please contact us for detailed specifications.

We offer multiple Materials for your choose, then manufacture the Best liquid cold plates to meet your application & working environment.

You can choose from:

Copper LCP - with excellent heat dissipation

Aluminum LCP - with excellent weight saving

Stainless steel cold Plate - with strong corrosion resistance

If you have any questions about the liquid cold plates & liquid cooling devices, please feel free to contact us for more information.

| Material | Thermal Conductivity (W/m·K) | Specific Gravity | Corrosion Resistance |

|---|---|---|---|

| Copper | 398 | 8.82 | Strong |

| Aluminum | 236 | 2.68 | Lightweight |

| Stainless | 17 | 7.93 | Comprehensive |

The best combination of the plate's material and coolant we suggest as follow:

Copper:

Aluminum :

Stainless: